Marc Stoiber recently sat down with Jim Nelson - Senior Marketing Manager at BC Hydro, and extracted Jim's list of seven psychological barriers to the general public accepting and embracing 'green' (Full interview).

But I believe there may be another even bigger barrier, that Jim has missed, and that is ignorance. I do not mean this in a negative way, but a true definition of the word way. You see, I consider myself fairly well informed on many energy efficiency issues and I definitely want to do the 'right' thing, even if it costs me a little extra in the short term.

But what is the 'right' thing?

I presently do not have enough knowledge to make that decision and I believe that many people would be in a similar or even worse situation. I have spent a LOT of time researching my upcoming build. I have literally spent hundreds if not thousands of hours over several years researching the best practices of building envelopes, HVAC, electrical efficiency, etc. But in many ways, I am no closer now to being able to make the 'right' decisions than when I started. There is so much information available these days thanks to the internet and search engines like Google. Answers are literally a few clicks away, but unfortunately much of these answers are conflicting depending on the bias or knowledge of the presenter. You are often unable to determine the best course of action.

This has often left me felling frustrated and can paralyze you from moving forward. An example is needed:

Over the last few days there has been a discussion on Linked-In asking about the sanity of using electric resistance baseboard heaters (Full Discussion - Building Science Group: Have we lost our minds when we use resistance heating in low load buildings?) I have been actively participating in this conversation because I though I could provide knowledgeable responses. But in the end, my assumptions were challenged leaving me wondering where I stood and feeling quite ignorant on the subject.

The basic premise I first had was based on the fact that I live in a region blessed with abundant clean energy, that being Hydro Electric. Currently, 90% of our Province's power comes from Hydro Electric generation with the balance being made up with Natural Gas fired Thermal (7.5%) and the rest is purchased energy (much of it from Alberta's coal generation with a smattering of renewable like wind). My logic was that I should utilize this 'green' energy in my upcoming build in order to reduce my carbon contribution to the planet. I would look at an air source heat pump ASHP (utilizes electricity to harvest free 'heat' from the air outside your home much in the same way as your refrigerator works to evacuate heat from its interior - just in reverse). I would use the heated refrigerant created by the ASHP to heat water (through the use of a heat exchanger) that would then be circulated through radiant panels I would place in my walls and ceilings (I will discuss why I will not do radiant floors in a future blog). In the summer time, I would reverse the heat pump and created chilled water that I could then use to help cool the home.

Many models of ASHP are available, but efficiencies as high as 4+ are available (meaning for every unit of electricity used, there will be 4 units of heat available). This sounds pretty good, doesn't it. But we are not done yet, we also have to take into account the source losses for the energy used and reduce our efficiency accordingly.

In a conversation I had with Dr. John Straube of Building Science Canada last winter, he suggested that an appropriate way to look at electricity generation may be to look at all of the generation sources feeding your particular electrical interconnection. I am part of the Western Electric Coordinating Council (WECC) interconnect which does have a lot of hydro electric generation, but is also supplemented by dirtier generation sources like coal. He suggested a source energy factor of 1.5 to 1.7 may be appropriate (for every kWh consumed at site, 1.5 to 1.7 kWh must be generated. The .5 to .7 lost kWh's represents transmission losses and generation inefficiencies). So a ASHP efficiency of 4 now drops to 2.35 - 2.67 when taking into account the source energy factor. Not as good but still at least 235% efficient.

What are the alternatives? For me, the logical alternative would be a high-efficiency-modulating-condensing-natural gas fired boiler. These type of units can have a site energy efficiency of 95%+ which translates into a source efficiency around 90% when adding in a 1.05% source energy factor (yes there are also 'transmission' losses - venting and pumping - in gas pipelines that account for most of the 5% loss). This is starting to look a lot less attractive. We have 90% efficient gas compared to 235%+ efficient electricity, and this formed the basis of my preliminary decision to not even re-connect the gas line up to my upcoming build.

Now the original Linked-in conversation was considering the use of electric resistance baseboard heaters. These are considered to have a 100% site efficiency which would translate into a 66% down to 59% source efficiency when taking into account the source energy factor of my region. This is poor in comparison with even the Natural Gas fired boiler efficiency. I would never consider such a heating source UNLESS the heating load was so low, due to the envelope efficiency, that electric resistance baseboards or radiant panels were the only heat source that could ramp down low enough to not overheat the dwelling. This can often be the case in dwellings that have extreme levels of insulation like those certified in the PassiveHaus program. These homes, by virtue of their certification, must have heating loads not exceeding 10W per square meter of living space. Unless the dwelling is quite large, this low of a load is often exceeded even by the smallest equipment currently available on the marketplace. Unfortunately, electric resistance baseboards are common in my region for some single family houses and abundant in multi-family housing.

On the surface, the decision looks easy - choose the 235% minimum efficient ASHP and that was were I stood a day ago. But I was then challenged by individuals in the discussion to visualize a larger picture. As mentioned I live in BC which has an abundance of hydro. My interconnect also has a high ratio of Hydro arguably giving it a source energy factor around 1.5 to 1.7. The rest of the USA in comparison is dirty, to just plain filthy, due to its heavy dependence on coal fired power plants. The average source energy factor for the USA is around 3.3 meaning for every unit of electric energy used in the home, 3.3 units of energy have to be created and added to the grid. This would bring our ASHP example down to a efficiency of 1.2 or 120%. Still better than gas but a lot worse than the average for my region. An electric baseboard on average in the USA would only have a efficiency of 30% when the source factor is taken into account - clearly a poor choice!

On the surface, no regions should use electric baseboards (unless the loads are VERY low) and in all regions, an efficient ASHP would be a better choice than even the most efficient gas boiler or forced air furnace. Again, the decision seems clear - right??

But what happens when a person in a region with 'green' hydro energy decides to use a gas fired heating system to reduce their electrical usage to allow more of that 'green' electricity to feed into the grid, and by doing so, hope to reduce the ratio of filthy coal power?

Does anyone benefit? Will the extra kWh's made available offset coal production or will the power just be consumed by increased demand of a non-energy conserving nation? How does one predict the actions of a consumer? How does one measure the result of such a decision? Should one use a 'green' electricity themselves, or use a dirtier energy so that they can pass on their clean power to users that only have filthy electricity available?

What is the right answer??? This is just one example of how difficult the right answer may be to obtain. An ignorance of the needed facts to make the right decision can paralyze a person from making any decision, which in turn could often lead to the adoption of the status quo (one of the barriers mentioned by Jim Nelson).

Now of course, I do not have this as an option. I must put some form of heating system into my planed build. To this end, I would appreciate input from those with relevant knowledge, that could help provide the information I need to make this decision.

Documenting the path one person is taking to achieve their version of sustainable living and construction.

Sunday, 30 December 2012

Barriers to 'Green' - Ignorance?

Labels:

Building Envelope,

BuiltGreen,

CFL electrical savings,

Electrical Efficiency,

Energy Efficient Building,

Energy Efficient Home,

Gas vs. Electricity,

LEED,

Passive House,

PassivHaus,

Sustainable Living

Location: North Vancouver

Marine Drive & Capilano Road, North Vancouver, BC V7P, Canada

Friday, 28 December 2012

Scotland Recycling and Vegetable Production

Well, it seems I may need to eat some crow and post some

updates to my comments regarding recycling and food production in Scotland.

I was contacted by a work colleague from a company I used to

work at, who is a proud Scott and had read my entry. He was not in agreement regarding my comments

on both the lack of recycling in Scotland and the lack of fresh-locally-grown vegetables. This interaction encouraged me to do a little

research.

I have contacted each of the establishments I stayed at and

have asked for the status of any recycling programs they may have. I will post the replies as received. In the meantime, I did some Google searching regarding recycling in Scotland and found some

great info. Programs do exist, but they seem to be limited in regions served and

frequency.

A great site to start at is http://www.recycleforscotland.com/recycle.asp. I was unable to get a match for any of the locations

we stayed at (may not have picked the right regions), but it seems the program

is centred around major urban regions only. For many of the listed areas, there does seem

to be great service including a ‘Blue Box’ program similar to our own. The site claims 93% of households in Scotland

have access to kerbside recycling facilities and the rest have “Recycling

Centres & Points” to take your recycled products to.

Another great site was http://www.zerowastescotland.org.uk/

which seems to be more of an educational and support organization and not into

the day to day activities of recycling.

It appears that through education and lobbying, this organization is

creating a greater awareness and need to recycle and reduce. It had great information on the need to

recycle and how recycling impacts our planet and material stream.

I then Goggled “Recycling Centres & Points” for each of

the locations we stayed at and found that some had a Centre close enough to be practical.

For instance, The Isle of Mull had a

centre in the very town we stayed in: Tobermory. Dornie had a point at their town centre. Some spots like the one in Balquhidder, did

not appear to have any reasonable options.

So I am a bit perplexed, both my wife and I are very used to

recycling at home and out and about in our daily lives. Even our ‘remote’ vacations in Tofino involve

separating all recycling into provided bins and taking the ‘loot’ with us to

drop off at the local centre (about 20 minutes away from Tofino near Long Beach)

when we are heading back to the Mainland.

So we are very used to looking for the bins, yet in all of the places we

stayed at, there was no obvious facility to separate out the recyclables from

the main garbage stream. I would imagine

that the Blue Box programs are fairly successful where available, after all, how much effort is

involved with throwing goods into a blue box compared to a garbage can. But if a resident has to store up the

recycling materials and bring them to a location that may be 30 minutes or more away, I

can understand (unfortunately) the hesitance many would have in participating

in such a program.

Does this mean that even though the facilities may be

available, they are not used by a large percentage of the population? Do only ‘urban’ residents participate? I do not have the answers. If you are reading this blog and live in

Scotland, I would love to hear from you.

As a side note – I also checked on Chicago and confirmed it

does NOT have an active recycle program.

The cost of the blue box program was turned down years ago and has to

date never been re-initiated.

So, now to the topic of Scottish produce. Again, I turned to Google. The first site I visited (http://www.scotland.org), advised that Scotland

grows 2,400 tonnes of raspberries, 4,600 tonnes of strawberries, and over a million tonnes of potatoes per year.

900 million eggs are produced annually, 1,300 million litres of milk and there

are more than two dozen cheese-makers across Scotland, ranging from the

industrial cheddar creameries to much smaller-scale cheese producers (I wonder if this is a misprint as we probably have 2 dozen cheese producers in our local Gulf Islands). The site went on to state "However,

beef is now the single most important sector of Scottish agriculture, worth

around £400 million a year: more than fruit, dairy and poultry combined!" It

also stated "The jewel in Scotland’s crown is her fish with nearly 200

shellfish farming companies. Salmon farming is the most important economic

development in the Highlands and Islands over the past 30 years, and the retail

sales value of Scottish salmon is around £300 million per annum. Scotland is

the world’s third largest producer of Atlantic salmon and enjoys a reputation

for quality fresh and added-value products such as smoked salmon."

http://www.nfus.org.uk

indicated that most of the soft fruit farming is in Tayside, Angus, and similar

fertile areas near Dundee (an area we did not visit but is near where my colleague grew up and forms the basis for his points of view).

I then visited http://forsythfreshproduce.co.uk/index/fresh-produce-seasonal-report

and read where all the salad ingredients come from basically the UK and

Holland. Most of the vegetables were

UK/France/Spain/Holland. These results

are for June which arguably is some of the best growing weather for crops like salad greens. This information aligns with the information we

were given by the ‘locals’ on our trip. “Veggies and Salad greens are not grown

locally and imports are often expensive”.

Additional sites indicated limited cauliflower, broccoli, and leek

production was also present in Scotland. It was

interesting to see that the Beef industry was so big in Scotland. We saw our first cow when leaving Scotland

near the Inverness airport, up until that time we only saw sheep.

http://eatscotland.visitscotland.com/food-drink/in-season/

was an excellent site to show what is potentially available fresh and local per

season.

So again, I am left a bit perplexed. If the growing conditions support fresh

vegetable production and they are available in the marketplace, Why are they not served

more often?

One of the locations we

stayed at (Monachyle

Mhor) had its own garden, and we did have some lovely cooked greens and

carrots while staying there, but our first real salad did not occur until the

end of our journey at The Old Inn in Gairlock.

Our stays in Edinburgh, Tobermory, Dornie, and Nairn had considerably

less choice for products that grew above the ground and left us wanting

more.

Why don’t more residents have

their own mini-gardens to bolster their vegetable availability? There certainly was the room for them in most

locations we visited. Are there difficulties

I am not aware of? Or is this just a

menu preference of many of the Scottish peoples? If so – why?

Where has the habit of game and root vegetable dominance originated? All topics for someone else’s blog I am

afraid but I would love to hear from any of you that may have some insight.

Our general experience was a starting lack of fresh vegetables being

made available to us during our journey.

This is the experience that initiated the original blog entry. The thought process then evolved into our

society’s general reliance on transporting fruits and vegetables and other

produce clear around the world, regardless of seasons. This is a global phenomenon and certainly is

much worse at my local supermarket than anything I encountered in the UK.

It is I believe not a sustainable

practice. It is one I hope to curb in my

personal life once I finish my upcoming build and would be able to set up

a garden in our back yard. I hope to

provide a majority of our vegetable needs for at least three seasons of the

year. Will I still buy Japanese mandarins

every Christmas, California cucumbers in the winter, and Mexican fruit in the

early spring? Probably, but in the mean

time, I am also trying to find many more local sources of produce that is grown

or raised in BC to limit the energy it takes to get food to my table.

Labels:

100 mile diet,

Organic Produce,

Owner Build House,

Passive House,

Recycling,

Sustainability,

Sustainable Living,

Where does our food come from?

Location: North Vancouver

Capilano College Archives, 2055 Purcell Way, North Vancouver, BC V7J 3H5, Canada

Thursday, 20 December 2012

May I present "The Enclosure"!

Well the days are ticking down and the stress level is rising, but I finally have a finished floor plan and reasonably advanced 3D model I can share with you. These are exciting times!

I have decided to call the project "The Enclosure" (sorry, no one won the $50 prize) to reflect my focus while designing.

I will use this blog and a new website that will launch in the months to come (www.TheEnclosure.ca) to promote what I feel are good decisions that encompass the below 9 guidelines. I also hope to include hourly construction photos during the entire build, live camera feed from two angles, manufacture’s technical information on the products I choose, and most important, real life figures as to cost and performance of the built dwelling, on this new website.

I hope to work with the utilities to provide live monitoring of site used energy and will also approach groups like HPO, BCIT, and the Building Envelope Engineering sector to design laboratory experiments that will provide real feedback, from the site, on the effectiveness and durability of different wall assembly structures.

To that end, I will design a 8ft high x 8ft long ‘opening’ on the north-top-floor-exterior-wall that will allow the installation of multiple ‘plug and play’ wall assemblies with instrumentation. This will allow the recording of wood moisture, relative humidity, temperatures, and heat flux through the various assemblies over time. The results, I hope, will allow calibration of computer models and determination by building officials as to appropriate assemblies to support in code changes for decades to come.

The instrument readings, I hope, would also be made available live on my website. In this way, the dwelling could have a real contribution to the scientific community and would help my goal of creating a legacy instead of a liability.

Now, if you read some of my earlier entries, you will see that this process started for me back in 1981 when I took my first drafting course in high school. Some of the concepts represented in a design I worked on through high school are still incorporated in my modern day design. Items like a low slopped roof, vaulted ceiling above the stairs and bedrooms, 'light wells', a ‘great room’, and a shop in the basement.

Other concepts are much more recent, like optimizing the floor space to be as compact as possible, incorporating SAFERhomes standards, generally following the principles of PassiveHaus, and most importantly - putting the building enclose much higher in the priorities list (with the larger portion of the budget to match).

I believe that in order to truly build a sustainable dwelling, you must follow these basic, but powerful, principles (placed in the order I believe is the most important) when laying out your design:

1) Build what society is probably going to want in terms of functionality for the upcoming decades (no sense building a small 750 square foot bungalow with 1 bedroom, that is just big enough for you, if as soon as you no longer choose to live there, it will be torn down).

2) Build as compact a floor plan as possible - Optimize your space and make only as large as needed. This does not mean that you have to feel cramped, just decide that having that 300 ft2 'master bath’, with room for a dining table in the middle of the floor, is probably not the best use of space (ours is only 118 ft2 and includes storage).

3) Limit the volume of the envelope by limiting the number of jogs in your wall design. This will reduce your overall heat loss and material use/cost. It will also make the dwelling a lot easier and cheaper to design and build in light of the new seismic requirements in British Columbia.

4) Build out of durable products that are appropriate for their intended purpose. Do not choose a ‘green’ product that does not last or protect the structure to an adequate level just because of its perceived "greenness".

5) Within the range of products available for each build element, chose ones with as little embodied energy as possible and that use as much renewable materials as possible (my focus will be to avoid as many oil based products possible).

6) Concentrate on energy reduction over site energy creation. This automatically dictates abiding by #2 and #3 above. It also dictates concentrating on the wall, roof, and floor slab assembly’s ability to resist thermal, water, and vapour flow over HVAC ‘conditioning. And in order to achieve your enclosure performance goals, you are going to have to ensure it gets a much larger slice of the budget pie, but you will be rewarded with smaller HVAC equipment sizing needs and reduced energy bills for decades to come.

7) Build Tight and Ventilate Right! YOU should decide where the ventilation air is coming from and not just leave it to chance. This gives you the opportunity to filter the air of pollen and other contaminates, and also to pre-warm/cool the air with stale air being exhausted from the dwelling. The controlled air exchange also keeps it out of the wall and roof assemblies where it can condense and ruin your day.

8) Size any required HVAC equipment to meet your reduced thermal loss or gain needs (remember parts of the continent actually need air conditioning). Oversized HVAC equipment is prevalent in the building industry, a practice that can often result in short run cycles that limit the equipment's ability to run efficiently and rid the dwelling of harmful pollutants or humidity.

9) Do everything possible to keep your partner happy in their design wishes. Yes this is still important, just at the bottom of the list and only accommodated up to the budgets constraints. So once you have paid for good windows, lots of insulation, and durable renewable products, there may not be a lot of money left for flashy but less useful features (from a future cost savings point of view), like granite counter tops in the washrooms, $50 a square foot Italian tile, $1000 shower heads (yes they exist), $30K kitchen cabinets, and the list goes on.

I will go into some of the design decisions with a lot more detail in future posting, but wanted to give you a quick overview of the design to date and some of the outstanding decisions and design tasks.

• Roof Truss Design

• Final Thermal Resistance Layer thicknesses for walls and roof assemblies.

• Window quality and U Values

• PHPP model to predict heating needs (PassiveHaus)

• Engineering of suspended garage slab

• ‘Approval’ of enclosure assemblies by my contacts in the building envelope community

• Plumbing Plan

• Electrical Plan

• HVAC equipment sizing and design (including choosing heating method – Forced Air/Hydronic/Air Source Heat Pump)

• Home Automation and low voltage design

• Site Survey

• Final Cladding design

• Final ceiling height decisions

• Layout drawings

• Permit Document Package

• Variance Application (for floor ratio*)

* My neighbourhood has its own zoning bylaw which has a requirement that upper floors can only be up to 75% of the main floor size. I am unsure of the purpose for this requirement, but it is at odds with keeping a dwelling as compact as possible (most efficient shape is a perfect square), and also runs against the new seismic requirements.

I will be asking for a relaxation of this requirement. I have made the upper floor as small as possible, but still fit in the desired 4 bedrooms and 2 bathrooms. The main floor I have also made as small as practical/desired to fit the rooms and functionality desired. This amounted to a split between the floors that is closer to an 85% ratio. I am trusting that the Municipal building department will concede to this logic and agree that this is an archaic requirement unfitting for our goal of an increasingly energy efficient building stock.

I have decided to call the project "The Enclosure" (sorry, no one won the $50 prize) to reflect my focus while designing.

I will use this blog and a new website that will launch in the months to come (www.TheEnclosure.ca) to promote what I feel are good decisions that encompass the below 9 guidelines. I also hope to include hourly construction photos during the entire build, live camera feed from two angles, manufacture’s technical information on the products I choose, and most important, real life figures as to cost and performance of the built dwelling, on this new website.

I hope to work with the utilities to provide live monitoring of site used energy and will also approach groups like HPO, BCIT, and the Building Envelope Engineering sector to design laboratory experiments that will provide real feedback, from the site, on the effectiveness and durability of different wall assembly structures.

To that end, I will design a 8ft high x 8ft long ‘opening’ on the north-top-floor-exterior-wall that will allow the installation of multiple ‘plug and play’ wall assemblies with instrumentation. This will allow the recording of wood moisture, relative humidity, temperatures, and heat flux through the various assemblies over time. The results, I hope, will allow calibration of computer models and determination by building officials as to appropriate assemblies to support in code changes for decades to come.

The instrument readings, I hope, would also be made available live on my website. In this way, the dwelling could have a real contribution to the scientific community and would help my goal of creating a legacy instead of a liability.

Now, if you read some of my earlier entries, you will see that this process started for me back in 1981 when I took my first drafting course in high school. Some of the concepts represented in a design I worked on through high school are still incorporated in my modern day design. Items like a low slopped roof, vaulted ceiling above the stairs and bedrooms, 'light wells', a ‘great room’, and a shop in the basement.

Other concepts are much more recent, like optimizing the floor space to be as compact as possible, incorporating SAFERhomes standards, generally following the principles of PassiveHaus, and most importantly - putting the building enclose much higher in the priorities list (with the larger portion of the budget to match).

I believe that in order to truly build a sustainable dwelling, you must follow these basic, but powerful, principles (placed in the order I believe is the most important) when laying out your design:

1) Build what society is probably going to want in terms of functionality for the upcoming decades (no sense building a small 750 square foot bungalow with 1 bedroom, that is just big enough for you, if as soon as you no longer choose to live there, it will be torn down).

2) Build as compact a floor plan as possible - Optimize your space and make only as large as needed. This does not mean that you have to feel cramped, just decide that having that 300 ft2 'master bath’, with room for a dining table in the middle of the floor, is probably not the best use of space (ours is only 118 ft2 and includes storage).

3) Limit the volume of the envelope by limiting the number of jogs in your wall design. This will reduce your overall heat loss and material use/cost. It will also make the dwelling a lot easier and cheaper to design and build in light of the new seismic requirements in British Columbia.

4) Build out of durable products that are appropriate for their intended purpose. Do not choose a ‘green’ product that does not last or protect the structure to an adequate level just because of its perceived "greenness".

5) Within the range of products available for each build element, chose ones with as little embodied energy as possible and that use as much renewable materials as possible (my focus will be to avoid as many oil based products possible).

6) Concentrate on energy reduction over site energy creation. This automatically dictates abiding by #2 and #3 above. It also dictates concentrating on the wall, roof, and floor slab assembly’s ability to resist thermal, water, and vapour flow over HVAC ‘conditioning. And in order to achieve your enclosure performance goals, you are going to have to ensure it gets a much larger slice of the budget pie, but you will be rewarded with smaller HVAC equipment sizing needs and reduced energy bills for decades to come.

7) Build Tight and Ventilate Right! YOU should decide where the ventilation air is coming from and not just leave it to chance. This gives you the opportunity to filter the air of pollen and other contaminates, and also to pre-warm/cool the air with stale air being exhausted from the dwelling. The controlled air exchange also keeps it out of the wall and roof assemblies where it can condense and ruin your day.

8) Size any required HVAC equipment to meet your reduced thermal loss or gain needs (remember parts of the continent actually need air conditioning). Oversized HVAC equipment is prevalent in the building industry, a practice that can often result in short run cycles that limit the equipment's ability to run efficiently and rid the dwelling of harmful pollutants or humidity.

9) Do everything possible to keep your partner happy in their design wishes. Yes this is still important, just at the bottom of the list and only accommodated up to the budgets constraints. So once you have paid for good windows, lots of insulation, and durable renewable products, there may not be a lot of money left for flashy but less useful features (from a future cost savings point of view), like granite counter tops in the washrooms, $50 a square foot Italian tile, $1000 shower heads (yes they exist), $30K kitchen cabinets, and the list goes on.

I will go into some of the design decisions with a lot more detail in future posting, but wanted to give you a quick overview of the design to date and some of the outstanding decisions and design tasks.

Tasks still to complete:

• Floor Truss Design• Roof Truss Design

• Final Thermal Resistance Layer thicknesses for walls and roof assemblies.

• Window quality and U Values

• PHPP model to predict heating needs (PassiveHaus)

• Engineering of suspended garage slab

• ‘Approval’ of enclosure assemblies by my contacts in the building envelope community

• Plumbing Plan

• Electrical Plan

• HVAC equipment sizing and design (including choosing heating method – Forced Air/Hydronic/Air Source Heat Pump)

• Home Automation and low voltage design

• Site Survey

• Final Cladding design

• Final ceiling height decisions

• Layout drawings

• Permit Document Package

• Variance Application (for floor ratio*)

* My neighbourhood has its own zoning bylaw which has a requirement that upper floors can only be up to 75% of the main floor size. I am unsure of the purpose for this requirement, but it is at odds with keeping a dwelling as compact as possible (most efficient shape is a perfect square), and also runs against the new seismic requirements.

I will be asking for a relaxation of this requirement. I have made the upper floor as small as possible, but still fit in the desired 4 bedrooms and 2 bathrooms. The main floor I have also made as small as practical/desired to fit the rooms and functionality desired. This amounted to a split between the floors that is closer to an 85% ratio. I am trusting that the Municipal building department will concede to this logic and agree that this is an archaic requirement unfitting for our goal of an increasingly energy efficient building stock.

Design and Floor Plan Illustrations

|

| Figure 1 NE Elevation |

- You will see that the north wall is almost featureless. I am fortunate to have the right sighting to make this work as I have an equally un-featured wall on the house about 15ft to the north of me. This will also support the plug and play wall ‘lab’ modules I hope to have sponsored by the building science community.

- You will also see that except for the cut-out around the garage, the dwelling is relatively square and uses roof lines to create interest instead of multiple wall jogs. This reduces the overall envelope volume which reduces cost and most importantly – heat loss.

- There is a full basement but no windows and only one north side-yard door access. The basement is dedicated to utility as you will see in the floor plans below. A future owner can create light wells and convert to a living suite if desired. This was not our focus (I have dreamed of a wood shop for decades and this was the only way I was going to get it on this property, due to zoning requirement) and a suite in the dwelling would have prevented an owner-build (dwellings with suites must use licensed contractors in my region).

|

| Figure 2 SE Elevation |

- Generous overhangs will protect the wall penetrations from wind driven rain and on the south side will also be designed to completely shade the windows during the summer’s mid-day heat to prevent interior solar gain.

- The foundations rise 6” above grade to allow the foundation to breath and protect the wall's wood structures from moisture related damage , but I wanted flush pedestrian access at all doors with no thresholds (to meet the SAFERhomes objectives), and so have dropped the first floor to hang off the side of the foundation on ledger boards.

- Notice the shallower foundation below the garage. The garage will have a suspended engineered slab to allow for useful space below, but I only needed a 8ft ceiling in this space (rest of basement will have 9ft ceiling to allow for tall projects in the wood shop).

- I still have decisions to make on the type of cladding. I am leaning to a natural stone feature wall at front and lightly stained tongue and grooved cedar cladding for the rest of the dwelling. These wood cladded areas may be broken up by cementitious panels to provide some architecture interest (say above and below windows).

|

| Figure 3 NW Elevation |

- Now before you all yell at me for the notch out, it is for good reason and not just ‘designed’ this way. One of the considerations when designing this house was three 125+ ft high cedars (see figure 5) on site that constrict the location and shape of the house’s outline (they have been there a lot longer than I have and have more right to the land than I). This notch is to accommodate the one cedar at the back of the house.

- The width of the house was further constrained by two more cedars to the south.

- I also wanted as shallow a house as possible to preserve as much of the backyard as possible.

- The two lookout windows on the north wall will let in some natural light and may also allow a view of the local mountains over the neighbour’s house and nearby trees.

- The square indicates the approximate location for the proposed lab ‘test panels’.

|

| Figure 4 SW Elevation |

- The low slope roofs work well with the neighbouring dwellings with the higher roof plane on the north to match that neighbours two storey home and the lower plane on the south the allow the neighbour on that side, living in a single storey dwelling (not likely to change in the decades to come), to still have some view of the mountains.

- The higher ratio of window glazing on the south will make good use of the solar gains that can be expected in the fall through spring, and then will be blocked out by the overhangs during the summer when the sun is high in the sky (will provide shading photos in a future blog).

- There is a chance that the living room, kitchen, and master bedroom will overheat in the summer based on the west glazing present. We will design for the addition of movable exterior solar shading on the west wall in case of this eventuality (because interior shading is hardly ever effective – heat is already on the wrong side of the envelope).

- The ‘look-out’ windows on top of the roof will provide natural light year round into the north side of the upper floor and solar heat gain from fall through spring.

- Before someone yells at me for the unsafe condition shown in the above photo, I still have to design a deck that will hang off the side of the structure, and be accessed through that French door on the second floor. Fortunately, the District has already agreed that as long as this is not supported by the ground below on posts, that it will not count towards my floor space (they typically only exempt the deck area if the structure is cantilevered out from the building which of course represents huge thermal bridging).

|

| Figure 5 Satellite photo of lot with both neighbour's lots also shown. |

- Top of photo is North.

- Two storey dwelling to north and single level dwelling to south.

- Yellow square indicates build lot and outline is rough location of planned build.

- White circles indicate location and approx. trunk size of nearby cedars.

- Notice a lack of shading for most of the south exposure. I will also have all 3 cedars de-limbed up to 30 ft and spiral pruned (you should never top a tree unless you are purposely consigning it to death). This will protect the roof surfaces from wind tossed branches and will provide full southern exposure to the lower fall and winter sun, but still provide great shading to about 30% of the summer days sun (9 AM through to about 11:45AM).

|

| Figure 6 First Floor |

Design Considerations:

- Place as much of the ‘living’ space on the south exposure as possible to capture day-time solar gain during fall to spring months. Also allows natural lighting to dominate most daytime lighting needs. On the flip side, keep as much of the utility on the north side as possible.

- Design room layouts to provide for the natural flow of people with as little ‘intersection’ conflicts as possible.

- Meet the needs of a home based business.

- Allow 12ft ceiling height in garage to accommodate a hoist.

- Open Floor Concept (makes smaller spaces look bigger and substantially reduces materials and build time). Ensure this 'open' feeling starts at the front door.

- Isolation of bathroom from ‘Great Room’.

- Hide stair from living area and make the most convenient for the family entrance (also ensure it took the least amount of space possible so no incorporated landings and changes in direction).

- Accommodate the family entrance off the garage as the ‘Main Entrance’ with the most closet storage.

- We even have some consideration to Feng Shui best practices as to best room layout, etc.

- Door, Hall, Stairs, and all squeeze point widths to meet SAFERhomes standard.

- Accommodate newly required seismic bands (both exterior and interior). Bands dictate location of windows and doors (interior and exterior)

|

| Figure 7 - Second Floor |

Design Considerations:

- All bedrooms on this floor.

- Ensure the number of bedrooms and bathrooms were suitable for what market in area expects. This is more than needed by my wife and I, but makes the house marketable when we no longer want to be here and reduces the likelihood that it will be torn down or significantly renovated for decades to come.

- Ensure guest bedroom is as far away from master bedroom as possible. This also holds true for the ‘TV’ room.

- Ensure sufficient closet space in all rooms (including bathrooms).

- Minimize extent of hall (another area grossly out of proportion in many 'modern' dwellings).

- Make bathrooms big enough without wasting space.

- Meet personal desire for more luxurious master bedroom located at the SW corner of the floor. Placing master bedroom in this location will allow that room to most benefit from solar gain in the shoulder months.

- Ensure walls are available for required seismic bands to line up with bands below.

- Meet my wife’s one and only requirement of a walk in closet in the master bedroom (yes I have it easy).

|

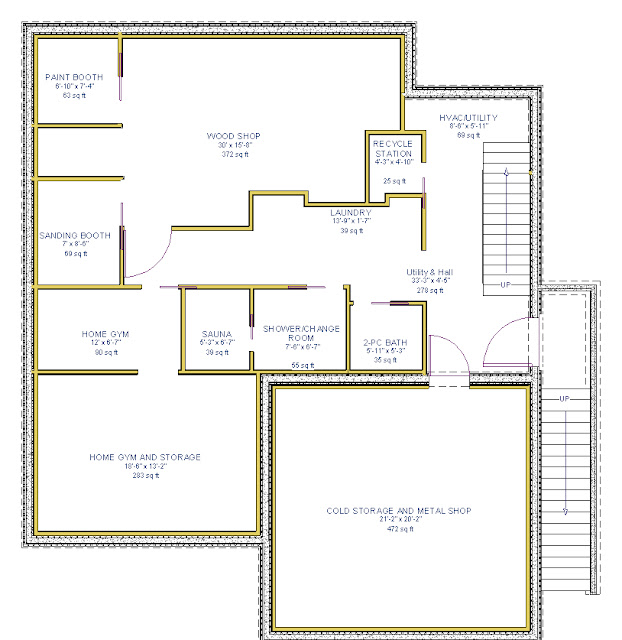

| Fig 8 - Basement |

Design Considerations:

- Contain all HVAC equipment.

- Provide Laundry facility where noise will not be disturbance to occupants. Also reduces flood hazard by not having it on upper floors (Holmes would be proud!).

- Provide space for home gym (first hurtle, actually using it is the hardest).

- Fulfill life long dream of a full wood shop.

- Provide Waste Vegetable Oil fuel processing station (upcoming blog entry).

- Provide for computer LAN vault.

- Provide for ample storage.

- Accommodate a Sauna.

Open Floor Truss Supplier?

Looking for a good open floor truss manufacturer for a project in the Greater Vancouver area (British Columbia). Any ideas?

Tuesday, 4 December 2012

Visualizing Wind Patterns

I remember multiple lectures during the BCIT BLDC 3050 & 3060 Building envelope courses that discussed the strange patterns wind can take when it hits a building. Well some smart individual figured out a way to visual it in real time.

Check out this cool video

Check out this cool video

Subscribe to:

Comments (Atom)