*** Update - Upon further reflection of this topic, I do feel there is one additional reason to perform energy upgrades and discuss it in my project journal http://www.theenclosure.ca/windy-house ***

This blog entry will analyze the air leakage of a 1954 house and relate that to the energy use and durability of the house.

Before I started tearing down my 1954 single storey 1500 sq ft bungalow to make way for theEnclosure.ca, I decided to have the house tested for air leakage by Michael and Deborah from H&H small home solutions inc (hhsss at shaw dot ca). H&H typically perform leakage testing to determine the EnerGuide rating for new construction, so this was going to be a new experience for them (and their blower door).

They came by in late March of 2014 after I had moved out but before I had completely emptied the house and before any deconstruction had been performed. The house was prepped by sealing the wood burning fireplace insert, range hood, and the through-wall mailbox before setting up the blower door.

We first ran the door in a B configuration and were unable to get up to the final test pressure of -50 Pa. But even in this configuration we got some scary results. I had not really made any great attempts to air seal this house over the years. There was weather stripping on 1 of the 3 doors, and the cedar siding had each coarse sealed to the next and the siding sealed to most of the window and door frames. But no attempts had been made to seal the interior interface with the attic plane and 1 of the doors had a cat door in it and the main door itself had very large gaps around it.

Prior to starting the test I had predicted an air leakage around 8-10 ACH (Air Changes per hour) @ -50 Pa, but early in the test we could tell it was going to be well above this. Deborah could tell just from the sound the fan was making (there previous worst house they tested was 11 ACH @ -50 Pa which was scary as it was new construction).

Right off the bat we reached 28 air exchanges at only -15 Pa! To give you an idea, 15 Pa relates to a wind speed of only 11 MPH. In the fall, I regularly recorded winds speeds on the property at this speed or higher so during those events all of that CONDITIONED air in the house was potentially changing over 28 times every hour. That is a lot of extra load on the heating plant and also explained the drafts my wife typically was feeling.

Over the next hour or so we tested at various configurations until we ran the fan at full open configuration (no restrictor plates). Only then could we get enough air volume to allow us to reach the target test pressure of -50 Pa. AT the full test pressure we recorded an air leakage of 21.74 ACH -50Pa.

Now wait, some of you may have noticed that that is less air leakage than what we observed at only -15 Pa. How is this possible you say?

Well, it is actually quite common. As more and more negative pressure is placed on a dwelling, the two surfaces on each side of an air path (leak) can start to come together. Eventually they can close up tight and stop that leak. This why I have a bit of an issue (actually quite a bit), of testing dwellings at -50 Pa. This relates to a wind speed of 20 Mph which is much higher than some locations would experience on a regular basis and much lower than other locations average wind speeds. As such, it is my opinion that their should be a standard test pressure PER geographical region. This could be a table much like the climate zone charts, but would be based on the average yearly mean wind speeds for a specific area. Homes in higher wind speed regions should be tested at higher pressures than homes in lower wind speed regions.

(Side bar - the reason the wind speed is important is that it is this force that will effect the pressures on a dwelling. Yes a house can depressurize under mechanical ventilation, but these are usually infrequent where wind depressurization or pressurization of the dwelling could occur for months at a time in windy locations).

So - these tests showed that the house was VERY leaky. What does that mean in terms of heating bills, comfort, and building durability.

Heating Bills

The truth is, this air leakage did not really make a huge difference in energy costs. My heating bills (for space and domestic hot water) were typically well under $2000 a year (We are under $2000 for both gas AND electrical use). As I am a heavy bath user, it is safe to say aprox 40% of this was domestic hot water use. This leaves an estimated $1000 in annual space heating costs. That works out to less than $100 a month, or well less than the cost of a weekend dinner out.

We typically had the heat set for 72-73F in the wintertime and basically did not tough the thermostat all year. It was not uncommon for the heat to come on during cold late spring and early fall evenings. We did however use a programmable thermostat that was set to come on at 7 AM, step down to about 65F at 8:30 AM, come back to temp at 4 PM, and step back down to about 68F at 11:30 PM. This was only partially for energy savings. The night time set backs were used because we had hydronic heating through large built-in wall registers (1-2 per room) via a 1980's gas boiler. The pipes went through and rubbed on the wood sub-floor assembly, so if the heat came on during the night the 'clicking' would wake me up. So we partially closed the bedroom door (so cats could still get in and out and not cause another source of nighttime wake-ups) and used an electric oil heater to maintain a comfortable temp in the bedroom.

While air tightness is important, it will not make a huge difference to your pocket book unless you have a very large and leaky house.

Comfort

The air leakage did however make a big difference in occupant comfort and should, in my opinion, be the biggest (and probably only) reason to upgrade an older home. The house was uncomfortable to sit in near any exterior wall in the winter months due to the drafts present. I was quite surprised when I saw how leaky the fixed, but home made, windows in the living room were. The builder had just placed the single pane of window glass against a wood surface and clamped it with a second wood component. At -15Pa, the wind just whistled through these locations. There is no question, that making the house more air tight would have made the house more comfortable.

Durability

Normally when one discusses the reasons for making a dwelling air tight, it is in the context of a 'modern' home with current levels of code required insulation. With modern levels of insulation, it is critical to ensure that air leakage does not occur, in order to prevent interior air leaking into the wall or roof assembly and condensing on cold sheathing. Left unchecked, this will often lead to mold and rot within the assembly.

The key here is the qty and location of the insulation. As soon as enough insulation is placed inside of the sheathing to allow the sheathing to cool down below the dew point of the interior air, you now have an assembly with a very high liability should any appreciable amount of air leak into that assembly from the conditioned interior. This is because air currents are the #1 mover of moisture next to bulk water leaks caused by plumbing leaks or incorrectly detailed cladding or roofs that permit bulk rain water entry into the assembly.

But in older houses like the one I took down (which had ZERO insulation in the walls), there is not enough insulation present to block the heat loss from the house enough to allow the sheathing to get to the dangerous dew point conditions. If you never reach the dew point, you can have huge amounts of moisture moving into the wall via air leakage and never have to worry about it because it stays in vapour form and just moves on through either to the outside of the dwelling or back into the inside. There is never liquid water that results from this air leakage. This is the reason why older homes have performed so well over many decades without the presence of air barriers, vapour barriers, or even effective water shedding surfaces. The heat loss has always been enough to 'cook' any accumulated moisture out of the assembly.

Conclusion

We have identified in this article that there is not a huge financial penalty for a leaky house. In my case, the costs per month for space heating were under $100/month in what is considered a cold-heating-dominated climate. This $1200 annual investment would not get very far in paying for a deep energy retrofit which typically would cost 10's of thousands of dollars. Lets say you could reduce the heating load even as much as 75% (purely speculative and most likely could not meet), this would represent $900 annual contribution to renovation costs.

A REALLY cheap stud level renovation for my home (including new windows and doors) would have been at least $60K (going to need to rip out parts of bathrooms and kitchens so most likely will totally renovate those rooms - my budget of $60 assumes very low end cabinets for these rooms).

A very intensive attic floor plane sealing regime would have been at least $15K (not going to do this process without bringing attic up to current insulation levels when done).

At a highly inflated $900 annual savings, these two projects would have a 66 and 17 year payback respectively. The attic plane sealing payback would most likely be much longer as only sealing this plane would probably represent only 50-70% of all air leakage present and therefore there would be reduced energy savings.

And my house did not represent an unusual annual energy bill. This US Energy Summary shows that for the West, the average annual winter heating bill per household varies between $1300 and $800 depending on year.

In the end, due to our really low energy costs, and the likely hood that they will not appreciably escalate for many decades due to Government interference, it makes very little sense to upgrade an existing homes energy performance for personal financial savings. Therefore the type of renovation needed to reduce air leakage or increase thermal performance, only makes sense if the home is being renovated anyway for cosmetic or occupant comfort reasons.

On a separate track - this logic also holds true when analyzing extreme new construction programs like Passive House. The costs to reach passive house levels of energy reduction will not be paid back over the lifespan of the dwelling in most cases. The added detriment of these programs is that the embodied energy of the insulation products built into these dwellings also do not have a pay back within the lifespan of the dwelling. Instead for new construction, it makes more sense to build a "Pretty Good House" (coined by Joe Lstiburek) and then use the excess capital available to either contribute to distributed or on-site energy generation.

It is however critical that air leakage be reduced down to a minimum (experts do not agree how little is adequate - but the number is somewhere between 1ACH+/-50 and 3ACH+/-50) for new construction or energy retrofits IF, you have built an assembly with enough insulation inboard of the sheathing to cause the sheathing to cool down to the dew point potential of any leaking interior air. If you build a safer assembly with the insulation outboard of the sheathing (or enough outboard to maintain the sheathing above the dew point potential), then while air leakage is still important to address from an energy loss standpoint (the costs to get it right during construction are minimal and will be paid back by reduced energy usage), it usually will not cause a durability concern for the assembly. This of course is all from the perspective of a heating dominated climate. The direction of flow and order of layers for the assembly are different in a cooling dominated or mixed climate.

Documenting the path one person is taking to achieve their version of sustainable living and construction.

Showing posts with label Energy Efficient Building. Show all posts

Showing posts with label Energy Efficient Building. Show all posts

Friday, 29 May 2015

Air Leakage of Old House - Does it matter?

Sunday, 1 September 2013

The Enclosure - Updated Exterior

I thought it might be time to provide an updated design photo showing the exterior of the dwelling as it is now modelled. I will use the through cavity window sill and head flashing to create borders around the windows (and doors). The infill will probably be simulated stucco cementitious panels.

Labels:

Building Envelope,

Built Green,

Energy Efficient Building,

Green Architecture,

LEED,

Passive House,

PassivHaus,

SAFERhomes,

Sustainability

Location: North Vancouver

Greater Vancouver, BC, Canada

Friday, 15 February 2013

The Power of Solar - Yes it works even in Vancouver!

I am sitting here in my home office getting some drawings completed. The sun is out and recently peaked out from hiding behind a cedar tree (which I will limb to a height of 35ft to get all of the winter sun in the future.. I keep the house pretty cold during the day and have an auxiliary electric cube heater in the office when needed. The house air temp is around 64ºF. Surfaces are between 50-65ºF (windows are 56ºF).

In my office that faces south and has the same single pane aluminum frame windows and un-insulated walls. I have not had the heat on since 9:30 this morning (4 hours ago). The air temp is 68ºF air temp (started out at the same 64ºF but within 30 minutes of direct sunlight spiked up), but the real difference are the surfaces. The window is 72ºF! All the other surfaces are between 66ºF and 75ºF depending on how much direct solar energy they are absorbing.

Pretty phenomenal really, if I can build a house that captures as much of this solar gain through the south side as possible why still significantly reducing the thermal loss through the envelope, I will be laughing all the way to the bank.

At the last BCBEC AGM, the first presenter was from RDH where they had studied the effects of solar gain on energy use in dwellings. The end result was that solar heat capture, even in Vancouver!, made sense and resulted in lower energy demands. The sweet spot utilized overhangs to prevent overheating in summer and windows with a 50% SHGC and a thermal resistance of U 0.16. This resulted in 22500 kWh of annual heating cooling energy. This was a significant reduction (10%) over the baseline 24500 kWh that utilized only 20% SHGC and U 0.35 windows.

This all of course is only practical if you have south exposure sun available. I am blessed with unobstructed full sun from around 9:00 AM to 2:00 PM with a couple of sporadic additional hours in the afternoon during the winter months.

In my office that faces south and has the same single pane aluminum frame windows and un-insulated walls. I have not had the heat on since 9:30 this morning (4 hours ago). The air temp is 68ºF air temp (started out at the same 64ºF but within 30 minutes of direct sunlight spiked up), but the real difference are the surfaces. The window is 72ºF! All the other surfaces are between 66ºF and 75ºF depending on how much direct solar energy they are absorbing.

Pretty phenomenal really, if I can build a house that captures as much of this solar gain through the south side as possible why still significantly reducing the thermal loss through the envelope, I will be laughing all the way to the bank.

At the last BCBEC AGM, the first presenter was from RDH where they had studied the effects of solar gain on energy use in dwellings. The end result was that solar heat capture, even in Vancouver!, made sense and resulted in lower energy demands. The sweet spot utilized overhangs to prevent overheating in summer and windows with a 50% SHGC and a thermal resistance of U 0.16. This resulted in 22500 kWh of annual heating cooling energy. This was a significant reduction (10%) over the baseline 24500 kWh that utilized only 20% SHGC and U 0.35 windows.

This all of course is only practical if you have south exposure sun available. I am blessed with unobstructed full sun from around 9:00 AM to 2:00 PM with a couple of sporadic additional hours in the afternoon during the winter months.

|

| Winter Sun will unfortunately be blocked from 2:00 PM til around 3:30 PM |

Labels:

Building Enclosure,

Building Envelope,

building science,

BuiltGreen,

Climate Change,

Energy Efficient Building,

Global Warming,

LEED,

Passive House

Location: North Vancouver

North Vancouver, BC, Canada

Sunday, 3 February 2013

Peak Oil 'Solved' - But Climate WIll Fry

It is scary when even the oil producers admits we are in trouble and that burning all of that oil may not be in our best interests.

http://www.vancouverobserver.com/blogs/climatesnapshot/peak-oil-solved-climate-will-fry-bp-report

When will we as a society wake up and start forcing our politicians to make a difference? When will we start making a difference in our own lives?

http://www.vancouverobserver.com/blogs/climatesnapshot/peak-oil-solved-climate-will-fry-bp-report

When will we as a society wake up and start forcing our politicians to make a difference? When will we start making a difference in our own lives?

Tuesday, 1 January 2013

Happy New Year!

Just wanted to wish you all Happy New Year out there in Webland.

I wish you Health, Happiness, and Prosperity for 2013!

Thanks for reading and making this blog such a success. It should be an exciting year with all engines ahead full on my upcoming build.

I wanted to leave you with my current two favourite quotes by Dr. John Straube:

When discussing the importance of envelope barrier components and their order in the assembly at recent seminar he stated; "You can pick your teeth, nose, and [butt], obviously the order you do so is very important!"

At a recent Building Science Experts’ Session it is reported that he stated; "Recirculating range hoods don't solve the IAQ problem. It's like a recirculating toilet, the stuff just goes round and round and never leaves."

I wish you Health, Happiness, and Prosperity for 2013!

Thanks for reading and making this blog such a success. It should be an exciting year with all engines ahead full on my upcoming build.

I wanted to leave you with my current two favourite quotes by Dr. John Straube:

When discussing the importance of envelope barrier components and their order in the assembly at recent seminar he stated; "You can pick your teeth, nose, and [butt], obviously the order you do so is very important!"

At a recent Building Science Experts’ Session it is reported that he stated; "Recirculating range hoods don't solve the IAQ problem. It's like a recirculating toilet, the stuff just goes round and round and never leaves."

Labels:

Building Enclosure,

Building Envelope,

Dr. John Straube,

Energy Efficient Building,

Energy Efficient Home,

LEED,

LEED Canada for Homes,

Passive House,

PassivHaus

Location: North Vancouver

Marine Drive & Capilano Road, North Vancouver, BC V7P, Canada

Sunday, 30 December 2012

Barriers to 'Green' - Ignorance?

Marc Stoiber recently sat down with Jim Nelson - Senior Marketing Manager at BC Hydro, and extracted Jim's list of seven psychological barriers to the general public accepting and embracing 'green' (Full interview).

But I believe there may be another even bigger barrier, that Jim has missed, and that is ignorance. I do not mean this in a negative way, but a true definition of the word way. You see, I consider myself fairly well informed on many energy efficiency issues and I definitely want to do the 'right' thing, even if it costs me a little extra in the short term.

But what is the 'right' thing?

I presently do not have enough knowledge to make that decision and I believe that many people would be in a similar or even worse situation. I have spent a LOT of time researching my upcoming build. I have literally spent hundreds if not thousands of hours over several years researching the best practices of building envelopes, HVAC, electrical efficiency, etc. But in many ways, I am no closer now to being able to make the 'right' decisions than when I started. There is so much information available these days thanks to the internet and search engines like Google. Answers are literally a few clicks away, but unfortunately much of these answers are conflicting depending on the bias or knowledge of the presenter. You are often unable to determine the best course of action.

This has often left me felling frustrated and can paralyze you from moving forward. An example is needed:

Over the last few days there has been a discussion on Linked-In asking about the sanity of using electric resistance baseboard heaters (Full Discussion - Building Science Group: Have we lost our minds when we use resistance heating in low load buildings?) I have been actively participating in this conversation because I though I could provide knowledgeable responses. But in the end, my assumptions were challenged leaving me wondering where I stood and feeling quite ignorant on the subject.

The basic premise I first had was based on the fact that I live in a region blessed with abundant clean energy, that being Hydro Electric. Currently, 90% of our Province's power comes from Hydro Electric generation with the balance being made up with Natural Gas fired Thermal (7.5%) and the rest is purchased energy (much of it from Alberta's coal generation with a smattering of renewable like wind). My logic was that I should utilize this 'green' energy in my upcoming build in order to reduce my carbon contribution to the planet. I would look at an air source heat pump ASHP (utilizes electricity to harvest free 'heat' from the air outside your home much in the same way as your refrigerator works to evacuate heat from its interior - just in reverse). I would use the heated refrigerant created by the ASHP to heat water (through the use of a heat exchanger) that would then be circulated through radiant panels I would place in my walls and ceilings (I will discuss why I will not do radiant floors in a future blog). In the summer time, I would reverse the heat pump and created chilled water that I could then use to help cool the home.

Many models of ASHP are available, but efficiencies as high as 4+ are available (meaning for every unit of electricity used, there will be 4 units of heat available). This sounds pretty good, doesn't it. But we are not done yet, we also have to take into account the source losses for the energy used and reduce our efficiency accordingly.

In a conversation I had with Dr. John Straube of Building Science Canada last winter, he suggested that an appropriate way to look at electricity generation may be to look at all of the generation sources feeding your particular electrical interconnection. I am part of the Western Electric Coordinating Council (WECC) interconnect which does have a lot of hydro electric generation, but is also supplemented by dirtier generation sources like coal. He suggested a source energy factor of 1.5 to 1.7 may be appropriate (for every kWh consumed at site, 1.5 to 1.7 kWh must be generated. The .5 to .7 lost kWh's represents transmission losses and generation inefficiencies). So a ASHP efficiency of 4 now drops to 2.35 - 2.67 when taking into account the source energy factor. Not as good but still at least 235% efficient.

What are the alternatives? For me, the logical alternative would be a high-efficiency-modulating-condensing-natural gas fired boiler. These type of units can have a site energy efficiency of 95%+ which translates into a source efficiency around 90% when adding in a 1.05% source energy factor (yes there are also 'transmission' losses - venting and pumping - in gas pipelines that account for most of the 5% loss). This is starting to look a lot less attractive. We have 90% efficient gas compared to 235%+ efficient electricity, and this formed the basis of my preliminary decision to not even re-connect the gas line up to my upcoming build.

Now the original Linked-in conversation was considering the use of electric resistance baseboard heaters. These are considered to have a 100% site efficiency which would translate into a 66% down to 59% source efficiency when taking into account the source energy factor of my region. This is poor in comparison with even the Natural Gas fired boiler efficiency. I would never consider such a heating source UNLESS the heating load was so low, due to the envelope efficiency, that electric resistance baseboards or radiant panels were the only heat source that could ramp down low enough to not overheat the dwelling. This can often be the case in dwellings that have extreme levels of insulation like those certified in the PassiveHaus program. These homes, by virtue of their certification, must have heating loads not exceeding 10W per square meter of living space. Unless the dwelling is quite large, this low of a load is often exceeded even by the smallest equipment currently available on the marketplace. Unfortunately, electric resistance baseboards are common in my region for some single family houses and abundant in multi-family housing.

On the surface, the decision looks easy - choose the 235% minimum efficient ASHP and that was were I stood a day ago. But I was then challenged by individuals in the discussion to visualize a larger picture. As mentioned I live in BC which has an abundance of hydro. My interconnect also has a high ratio of Hydro arguably giving it a source energy factor around 1.5 to 1.7. The rest of the USA in comparison is dirty, to just plain filthy, due to its heavy dependence on coal fired power plants. The average source energy factor for the USA is around 3.3 meaning for every unit of electric energy used in the home, 3.3 units of energy have to be created and added to the grid. This would bring our ASHP example down to a efficiency of 1.2 or 120%. Still better than gas but a lot worse than the average for my region. An electric baseboard on average in the USA would only have a efficiency of 30% when the source factor is taken into account - clearly a poor choice!

On the surface, no regions should use electric baseboards (unless the loads are VERY low) and in all regions, an efficient ASHP would be a better choice than even the most efficient gas boiler or forced air furnace. Again, the decision seems clear - right??

But what happens when a person in a region with 'green' hydro energy decides to use a gas fired heating system to reduce their electrical usage to allow more of that 'green' electricity to feed into the grid, and by doing so, hope to reduce the ratio of filthy coal power?

Does anyone benefit? Will the extra kWh's made available offset coal production or will the power just be consumed by increased demand of a non-energy conserving nation? How does one predict the actions of a consumer? How does one measure the result of such a decision? Should one use a 'green' electricity themselves, or use a dirtier energy so that they can pass on their clean power to users that only have filthy electricity available?

What is the right answer??? This is just one example of how difficult the right answer may be to obtain. An ignorance of the needed facts to make the right decision can paralyze a person from making any decision, which in turn could often lead to the adoption of the status quo (one of the barriers mentioned by Jim Nelson).

Now of course, I do not have this as an option. I must put some form of heating system into my planed build. To this end, I would appreciate input from those with relevant knowledge, that could help provide the information I need to make this decision.

But I believe there may be another even bigger barrier, that Jim has missed, and that is ignorance. I do not mean this in a negative way, but a true definition of the word way. You see, I consider myself fairly well informed on many energy efficiency issues and I definitely want to do the 'right' thing, even if it costs me a little extra in the short term.

But what is the 'right' thing?

I presently do not have enough knowledge to make that decision and I believe that many people would be in a similar or even worse situation. I have spent a LOT of time researching my upcoming build. I have literally spent hundreds if not thousands of hours over several years researching the best practices of building envelopes, HVAC, electrical efficiency, etc. But in many ways, I am no closer now to being able to make the 'right' decisions than when I started. There is so much information available these days thanks to the internet and search engines like Google. Answers are literally a few clicks away, but unfortunately much of these answers are conflicting depending on the bias or knowledge of the presenter. You are often unable to determine the best course of action.

This has often left me felling frustrated and can paralyze you from moving forward. An example is needed:

Over the last few days there has been a discussion on Linked-In asking about the sanity of using electric resistance baseboard heaters (Full Discussion - Building Science Group: Have we lost our minds when we use resistance heating in low load buildings?) I have been actively participating in this conversation because I though I could provide knowledgeable responses. But in the end, my assumptions were challenged leaving me wondering where I stood and feeling quite ignorant on the subject.

The basic premise I first had was based on the fact that I live in a region blessed with abundant clean energy, that being Hydro Electric. Currently, 90% of our Province's power comes from Hydro Electric generation with the balance being made up with Natural Gas fired Thermal (7.5%) and the rest is purchased energy (much of it from Alberta's coal generation with a smattering of renewable like wind). My logic was that I should utilize this 'green' energy in my upcoming build in order to reduce my carbon contribution to the planet. I would look at an air source heat pump ASHP (utilizes electricity to harvest free 'heat' from the air outside your home much in the same way as your refrigerator works to evacuate heat from its interior - just in reverse). I would use the heated refrigerant created by the ASHP to heat water (through the use of a heat exchanger) that would then be circulated through radiant panels I would place in my walls and ceilings (I will discuss why I will not do radiant floors in a future blog). In the summer time, I would reverse the heat pump and created chilled water that I could then use to help cool the home.

Many models of ASHP are available, but efficiencies as high as 4+ are available (meaning for every unit of electricity used, there will be 4 units of heat available). This sounds pretty good, doesn't it. But we are not done yet, we also have to take into account the source losses for the energy used and reduce our efficiency accordingly.

In a conversation I had with Dr. John Straube of Building Science Canada last winter, he suggested that an appropriate way to look at electricity generation may be to look at all of the generation sources feeding your particular electrical interconnection. I am part of the Western Electric Coordinating Council (WECC) interconnect which does have a lot of hydro electric generation, but is also supplemented by dirtier generation sources like coal. He suggested a source energy factor of 1.5 to 1.7 may be appropriate (for every kWh consumed at site, 1.5 to 1.7 kWh must be generated. The .5 to .7 lost kWh's represents transmission losses and generation inefficiencies). So a ASHP efficiency of 4 now drops to 2.35 - 2.67 when taking into account the source energy factor. Not as good but still at least 235% efficient.

What are the alternatives? For me, the logical alternative would be a high-efficiency-modulating-condensing-natural gas fired boiler. These type of units can have a site energy efficiency of 95%+ which translates into a source efficiency around 90% when adding in a 1.05% source energy factor (yes there are also 'transmission' losses - venting and pumping - in gas pipelines that account for most of the 5% loss). This is starting to look a lot less attractive. We have 90% efficient gas compared to 235%+ efficient electricity, and this formed the basis of my preliminary decision to not even re-connect the gas line up to my upcoming build.

Now the original Linked-in conversation was considering the use of electric resistance baseboard heaters. These are considered to have a 100% site efficiency which would translate into a 66% down to 59% source efficiency when taking into account the source energy factor of my region. This is poor in comparison with even the Natural Gas fired boiler efficiency. I would never consider such a heating source UNLESS the heating load was so low, due to the envelope efficiency, that electric resistance baseboards or radiant panels were the only heat source that could ramp down low enough to not overheat the dwelling. This can often be the case in dwellings that have extreme levels of insulation like those certified in the PassiveHaus program. These homes, by virtue of their certification, must have heating loads not exceeding 10W per square meter of living space. Unless the dwelling is quite large, this low of a load is often exceeded even by the smallest equipment currently available on the marketplace. Unfortunately, electric resistance baseboards are common in my region for some single family houses and abundant in multi-family housing.

On the surface, the decision looks easy - choose the 235% minimum efficient ASHP and that was were I stood a day ago. But I was then challenged by individuals in the discussion to visualize a larger picture. As mentioned I live in BC which has an abundance of hydro. My interconnect also has a high ratio of Hydro arguably giving it a source energy factor around 1.5 to 1.7. The rest of the USA in comparison is dirty, to just plain filthy, due to its heavy dependence on coal fired power plants. The average source energy factor for the USA is around 3.3 meaning for every unit of electric energy used in the home, 3.3 units of energy have to be created and added to the grid. This would bring our ASHP example down to a efficiency of 1.2 or 120%. Still better than gas but a lot worse than the average for my region. An electric baseboard on average in the USA would only have a efficiency of 30% when the source factor is taken into account - clearly a poor choice!

On the surface, no regions should use electric baseboards (unless the loads are VERY low) and in all regions, an efficient ASHP would be a better choice than even the most efficient gas boiler or forced air furnace. Again, the decision seems clear - right??

But what happens when a person in a region with 'green' hydro energy decides to use a gas fired heating system to reduce their electrical usage to allow more of that 'green' electricity to feed into the grid, and by doing so, hope to reduce the ratio of filthy coal power?

Does anyone benefit? Will the extra kWh's made available offset coal production or will the power just be consumed by increased demand of a non-energy conserving nation? How does one predict the actions of a consumer? How does one measure the result of such a decision? Should one use a 'green' electricity themselves, or use a dirtier energy so that they can pass on their clean power to users that only have filthy electricity available?

What is the right answer??? This is just one example of how difficult the right answer may be to obtain. An ignorance of the needed facts to make the right decision can paralyze a person from making any decision, which in turn could often lead to the adoption of the status quo (one of the barriers mentioned by Jim Nelson).

Now of course, I do not have this as an option. I must put some form of heating system into my planed build. To this end, I would appreciate input from those with relevant knowledge, that could help provide the information I need to make this decision.

Labels:

Building Envelope,

BuiltGreen,

CFL electrical savings,

Electrical Efficiency,

Energy Efficient Building,

Energy Efficient Home,

Gas vs. Electricity,

LEED,

Passive House,

PassivHaus,

Sustainable Living

Location: North Vancouver

Marine Drive & Capilano Road, North Vancouver, BC V7P, Canada

Thursday, 20 December 2012

May I present "The Enclosure"!

Well the days are ticking down and the stress level is rising, but I finally have a finished floor plan and reasonably advanced 3D model I can share with you. These are exciting times!

I have decided to call the project "The Enclosure" (sorry, no one won the $50 prize) to reflect my focus while designing.

I will use this blog and a new website that will launch in the months to come (www.TheEnclosure.ca) to promote what I feel are good decisions that encompass the below 9 guidelines. I also hope to include hourly construction photos during the entire build, live camera feed from two angles, manufacture’s technical information on the products I choose, and most important, real life figures as to cost and performance of the built dwelling, on this new website.

I hope to work with the utilities to provide live monitoring of site used energy and will also approach groups like HPO, BCIT, and the Building Envelope Engineering sector to design laboratory experiments that will provide real feedback, from the site, on the effectiveness and durability of different wall assembly structures.

To that end, I will design a 8ft high x 8ft long ‘opening’ on the north-top-floor-exterior-wall that will allow the installation of multiple ‘plug and play’ wall assemblies with instrumentation. This will allow the recording of wood moisture, relative humidity, temperatures, and heat flux through the various assemblies over time. The results, I hope, will allow calibration of computer models and determination by building officials as to appropriate assemblies to support in code changes for decades to come.

The instrument readings, I hope, would also be made available live on my website. In this way, the dwelling could have a real contribution to the scientific community and would help my goal of creating a legacy instead of a liability.

Now, if you read some of my earlier entries, you will see that this process started for me back in 1981 when I took my first drafting course in high school. Some of the concepts represented in a design I worked on through high school are still incorporated in my modern day design. Items like a low slopped roof, vaulted ceiling above the stairs and bedrooms, 'light wells', a ‘great room’, and a shop in the basement.

Other concepts are much more recent, like optimizing the floor space to be as compact as possible, incorporating SAFERhomes standards, generally following the principles of PassiveHaus, and most importantly - putting the building enclose much higher in the priorities list (with the larger portion of the budget to match).

I believe that in order to truly build a sustainable dwelling, you must follow these basic, but powerful, principles (placed in the order I believe is the most important) when laying out your design:

1) Build what society is probably going to want in terms of functionality for the upcoming decades (no sense building a small 750 square foot bungalow with 1 bedroom, that is just big enough for you, if as soon as you no longer choose to live there, it will be torn down).

2) Build as compact a floor plan as possible - Optimize your space and make only as large as needed. This does not mean that you have to feel cramped, just decide that having that 300 ft2 'master bath’, with room for a dining table in the middle of the floor, is probably not the best use of space (ours is only 118 ft2 and includes storage).

3) Limit the volume of the envelope by limiting the number of jogs in your wall design. This will reduce your overall heat loss and material use/cost. It will also make the dwelling a lot easier and cheaper to design and build in light of the new seismic requirements in British Columbia.

4) Build out of durable products that are appropriate for their intended purpose. Do not choose a ‘green’ product that does not last or protect the structure to an adequate level just because of its perceived "greenness".

5) Within the range of products available for each build element, chose ones with as little embodied energy as possible and that use as much renewable materials as possible (my focus will be to avoid as many oil based products possible).

6) Concentrate on energy reduction over site energy creation. This automatically dictates abiding by #2 and #3 above. It also dictates concentrating on the wall, roof, and floor slab assembly’s ability to resist thermal, water, and vapour flow over HVAC ‘conditioning. And in order to achieve your enclosure performance goals, you are going to have to ensure it gets a much larger slice of the budget pie, but you will be rewarded with smaller HVAC equipment sizing needs and reduced energy bills for decades to come.

7) Build Tight and Ventilate Right! YOU should decide where the ventilation air is coming from and not just leave it to chance. This gives you the opportunity to filter the air of pollen and other contaminates, and also to pre-warm/cool the air with stale air being exhausted from the dwelling. The controlled air exchange also keeps it out of the wall and roof assemblies where it can condense and ruin your day.

8) Size any required HVAC equipment to meet your reduced thermal loss or gain needs (remember parts of the continent actually need air conditioning). Oversized HVAC equipment is prevalent in the building industry, a practice that can often result in short run cycles that limit the equipment's ability to run efficiently and rid the dwelling of harmful pollutants or humidity.

9) Do everything possible to keep your partner happy in their design wishes. Yes this is still important, just at the bottom of the list and only accommodated up to the budgets constraints. So once you have paid for good windows, lots of insulation, and durable renewable products, there may not be a lot of money left for flashy but less useful features (from a future cost savings point of view), like granite counter tops in the washrooms, $50 a square foot Italian tile, $1000 shower heads (yes they exist), $30K kitchen cabinets, and the list goes on.

I will go into some of the design decisions with a lot more detail in future posting, but wanted to give you a quick overview of the design to date and some of the outstanding decisions and design tasks.

• Roof Truss Design

• Final Thermal Resistance Layer thicknesses for walls and roof assemblies.

• Window quality and U Values

• PHPP model to predict heating needs (PassiveHaus)

• Engineering of suspended garage slab

• ‘Approval’ of enclosure assemblies by my contacts in the building envelope community

• Plumbing Plan

• Electrical Plan

• HVAC equipment sizing and design (including choosing heating method – Forced Air/Hydronic/Air Source Heat Pump)

• Home Automation and low voltage design

• Site Survey

• Final Cladding design

• Final ceiling height decisions

• Layout drawings

• Permit Document Package

• Variance Application (for floor ratio*)

* My neighbourhood has its own zoning bylaw which has a requirement that upper floors can only be up to 75% of the main floor size. I am unsure of the purpose for this requirement, but it is at odds with keeping a dwelling as compact as possible (most efficient shape is a perfect square), and also runs against the new seismic requirements.

I will be asking for a relaxation of this requirement. I have made the upper floor as small as possible, but still fit in the desired 4 bedrooms and 2 bathrooms. The main floor I have also made as small as practical/desired to fit the rooms and functionality desired. This amounted to a split between the floors that is closer to an 85% ratio. I am trusting that the Municipal building department will concede to this logic and agree that this is an archaic requirement unfitting for our goal of an increasingly energy efficient building stock.

I have decided to call the project "The Enclosure" (sorry, no one won the $50 prize) to reflect my focus while designing.

I will use this blog and a new website that will launch in the months to come (www.TheEnclosure.ca) to promote what I feel are good decisions that encompass the below 9 guidelines. I also hope to include hourly construction photos during the entire build, live camera feed from two angles, manufacture’s technical information on the products I choose, and most important, real life figures as to cost and performance of the built dwelling, on this new website.

I hope to work with the utilities to provide live monitoring of site used energy and will also approach groups like HPO, BCIT, and the Building Envelope Engineering sector to design laboratory experiments that will provide real feedback, from the site, on the effectiveness and durability of different wall assembly structures.

To that end, I will design a 8ft high x 8ft long ‘opening’ on the north-top-floor-exterior-wall that will allow the installation of multiple ‘plug and play’ wall assemblies with instrumentation. This will allow the recording of wood moisture, relative humidity, temperatures, and heat flux through the various assemblies over time. The results, I hope, will allow calibration of computer models and determination by building officials as to appropriate assemblies to support in code changes for decades to come.

The instrument readings, I hope, would also be made available live on my website. In this way, the dwelling could have a real contribution to the scientific community and would help my goal of creating a legacy instead of a liability.

Now, if you read some of my earlier entries, you will see that this process started for me back in 1981 when I took my first drafting course in high school. Some of the concepts represented in a design I worked on through high school are still incorporated in my modern day design. Items like a low slopped roof, vaulted ceiling above the stairs and bedrooms, 'light wells', a ‘great room’, and a shop in the basement.

Other concepts are much more recent, like optimizing the floor space to be as compact as possible, incorporating SAFERhomes standards, generally following the principles of PassiveHaus, and most importantly - putting the building enclose much higher in the priorities list (with the larger portion of the budget to match).

I believe that in order to truly build a sustainable dwelling, you must follow these basic, but powerful, principles (placed in the order I believe is the most important) when laying out your design:

1) Build what society is probably going to want in terms of functionality for the upcoming decades (no sense building a small 750 square foot bungalow with 1 bedroom, that is just big enough for you, if as soon as you no longer choose to live there, it will be torn down).

2) Build as compact a floor plan as possible - Optimize your space and make only as large as needed. This does not mean that you have to feel cramped, just decide that having that 300 ft2 'master bath’, with room for a dining table in the middle of the floor, is probably not the best use of space (ours is only 118 ft2 and includes storage).

3) Limit the volume of the envelope by limiting the number of jogs in your wall design. This will reduce your overall heat loss and material use/cost. It will also make the dwelling a lot easier and cheaper to design and build in light of the new seismic requirements in British Columbia.

4) Build out of durable products that are appropriate for their intended purpose. Do not choose a ‘green’ product that does not last or protect the structure to an adequate level just because of its perceived "greenness".

5) Within the range of products available for each build element, chose ones with as little embodied energy as possible and that use as much renewable materials as possible (my focus will be to avoid as many oil based products possible).

6) Concentrate on energy reduction over site energy creation. This automatically dictates abiding by #2 and #3 above. It also dictates concentrating on the wall, roof, and floor slab assembly’s ability to resist thermal, water, and vapour flow over HVAC ‘conditioning. And in order to achieve your enclosure performance goals, you are going to have to ensure it gets a much larger slice of the budget pie, but you will be rewarded with smaller HVAC equipment sizing needs and reduced energy bills for decades to come.

7) Build Tight and Ventilate Right! YOU should decide where the ventilation air is coming from and not just leave it to chance. This gives you the opportunity to filter the air of pollen and other contaminates, and also to pre-warm/cool the air with stale air being exhausted from the dwelling. The controlled air exchange also keeps it out of the wall and roof assemblies where it can condense and ruin your day.

8) Size any required HVAC equipment to meet your reduced thermal loss or gain needs (remember parts of the continent actually need air conditioning). Oversized HVAC equipment is prevalent in the building industry, a practice that can often result in short run cycles that limit the equipment's ability to run efficiently and rid the dwelling of harmful pollutants or humidity.

9) Do everything possible to keep your partner happy in their design wishes. Yes this is still important, just at the bottom of the list and only accommodated up to the budgets constraints. So once you have paid for good windows, lots of insulation, and durable renewable products, there may not be a lot of money left for flashy but less useful features (from a future cost savings point of view), like granite counter tops in the washrooms, $50 a square foot Italian tile, $1000 shower heads (yes they exist), $30K kitchen cabinets, and the list goes on.

I will go into some of the design decisions with a lot more detail in future posting, but wanted to give you a quick overview of the design to date and some of the outstanding decisions and design tasks.

Tasks still to complete:

• Floor Truss Design• Roof Truss Design

• Final Thermal Resistance Layer thicknesses for walls and roof assemblies.

• Window quality and U Values

• PHPP model to predict heating needs (PassiveHaus)

• Engineering of suspended garage slab

• ‘Approval’ of enclosure assemblies by my contacts in the building envelope community

• Plumbing Plan

• Electrical Plan

• HVAC equipment sizing and design (including choosing heating method – Forced Air/Hydronic/Air Source Heat Pump)

• Home Automation and low voltage design

• Site Survey

• Final Cladding design

• Final ceiling height decisions

• Layout drawings

• Permit Document Package

• Variance Application (for floor ratio*)

* My neighbourhood has its own zoning bylaw which has a requirement that upper floors can only be up to 75% of the main floor size. I am unsure of the purpose for this requirement, but it is at odds with keeping a dwelling as compact as possible (most efficient shape is a perfect square), and also runs against the new seismic requirements.

I will be asking for a relaxation of this requirement. I have made the upper floor as small as possible, but still fit in the desired 4 bedrooms and 2 bathrooms. The main floor I have also made as small as practical/desired to fit the rooms and functionality desired. This amounted to a split between the floors that is closer to an 85% ratio. I am trusting that the Municipal building department will concede to this logic and agree that this is an archaic requirement unfitting for our goal of an increasingly energy efficient building stock.

Design and Floor Plan Illustrations

|

| Figure 1 NE Elevation |

- You will see that the north wall is almost featureless. I am fortunate to have the right sighting to make this work as I have an equally un-featured wall on the house about 15ft to the north of me. This will also support the plug and play wall ‘lab’ modules I hope to have sponsored by the building science community.

- You will also see that except for the cut-out around the garage, the dwelling is relatively square and uses roof lines to create interest instead of multiple wall jogs. This reduces the overall envelope volume which reduces cost and most importantly – heat loss.

- There is a full basement but no windows and only one north side-yard door access. The basement is dedicated to utility as you will see in the floor plans below. A future owner can create light wells and convert to a living suite if desired. This was not our focus (I have dreamed of a wood shop for decades and this was the only way I was going to get it on this property, due to zoning requirement) and a suite in the dwelling would have prevented an owner-build (dwellings with suites must use licensed contractors in my region).

|

| Figure 2 SE Elevation |

- Generous overhangs will protect the wall penetrations from wind driven rain and on the south side will also be designed to completely shade the windows during the summer’s mid-day heat to prevent interior solar gain.

- The foundations rise 6” above grade to allow the foundation to breath and protect the wall's wood structures from moisture related damage , but I wanted flush pedestrian access at all doors with no thresholds (to meet the SAFERhomes objectives), and so have dropped the first floor to hang off the side of the foundation on ledger boards.

- Notice the shallower foundation below the garage. The garage will have a suspended engineered slab to allow for useful space below, but I only needed a 8ft ceiling in this space (rest of basement will have 9ft ceiling to allow for tall projects in the wood shop).

- I still have decisions to make on the type of cladding. I am leaning to a natural stone feature wall at front and lightly stained tongue and grooved cedar cladding for the rest of the dwelling. These wood cladded areas may be broken up by cementitious panels to provide some architecture interest (say above and below windows).

|

| Figure 3 NW Elevation |

- Now before you all yell at me for the notch out, it is for good reason and not just ‘designed’ this way. One of the considerations when designing this house was three 125+ ft high cedars (see figure 5) on site that constrict the location and shape of the house’s outline (they have been there a lot longer than I have and have more right to the land than I). This notch is to accommodate the one cedar at the back of the house.

- The width of the house was further constrained by two more cedars to the south.

- I also wanted as shallow a house as possible to preserve as much of the backyard as possible.

- The two lookout windows on the north wall will let in some natural light and may also allow a view of the local mountains over the neighbour’s house and nearby trees.

- The square indicates the approximate location for the proposed lab ‘test panels’.

|

| Figure 4 SW Elevation |

- The low slope roofs work well with the neighbouring dwellings with the higher roof plane on the north to match that neighbours two storey home and the lower plane on the south the allow the neighbour on that side, living in a single storey dwelling (not likely to change in the decades to come), to still have some view of the mountains.

- The higher ratio of window glazing on the south will make good use of the solar gains that can be expected in the fall through spring, and then will be blocked out by the overhangs during the summer when the sun is high in the sky (will provide shading photos in a future blog).

- There is a chance that the living room, kitchen, and master bedroom will overheat in the summer based on the west glazing present. We will design for the addition of movable exterior solar shading on the west wall in case of this eventuality (because interior shading is hardly ever effective – heat is already on the wrong side of the envelope).

- The ‘look-out’ windows on top of the roof will provide natural light year round into the north side of the upper floor and solar heat gain from fall through spring.

- Before someone yells at me for the unsafe condition shown in the above photo, I still have to design a deck that will hang off the side of the structure, and be accessed through that French door on the second floor. Fortunately, the District has already agreed that as long as this is not supported by the ground below on posts, that it will not count towards my floor space (they typically only exempt the deck area if the structure is cantilevered out from the building which of course represents huge thermal bridging).

|

| Figure 5 Satellite photo of lot with both neighbour's lots also shown. |

- Top of photo is North.

- Two storey dwelling to north and single level dwelling to south.

- Yellow square indicates build lot and outline is rough location of planned build.

- White circles indicate location and approx. trunk size of nearby cedars.

- Notice a lack of shading for most of the south exposure. I will also have all 3 cedars de-limbed up to 30 ft and spiral pruned (you should never top a tree unless you are purposely consigning it to death). This will protect the roof surfaces from wind tossed branches and will provide full southern exposure to the lower fall and winter sun, but still provide great shading to about 30% of the summer days sun (9 AM through to about 11:45AM).

|

| Figure 6 First Floor |

Design Considerations:

- Place as much of the ‘living’ space on the south exposure as possible to capture day-time solar gain during fall to spring months. Also allows natural lighting to dominate most daytime lighting needs. On the flip side, keep as much of the utility on the north side as possible.

- Design room layouts to provide for the natural flow of people with as little ‘intersection’ conflicts as possible.

- Meet the needs of a home based business.

- Allow 12ft ceiling height in garage to accommodate a hoist.

- Open Floor Concept (makes smaller spaces look bigger and substantially reduces materials and build time). Ensure this 'open' feeling starts at the front door.

- Isolation of bathroom from ‘Great Room’.

- Hide stair from living area and make the most convenient for the family entrance (also ensure it took the least amount of space possible so no incorporated landings and changes in direction).

- Accommodate the family entrance off the garage as the ‘Main Entrance’ with the most closet storage.

- We even have some consideration to Feng Shui best practices as to best room layout, etc.

- Door, Hall, Stairs, and all squeeze point widths to meet SAFERhomes standard.

- Accommodate newly required seismic bands (both exterior and interior). Bands dictate location of windows and doors (interior and exterior)

|

| Figure 7 - Second Floor |

Design Considerations:

- All bedrooms on this floor.

- Ensure the number of bedrooms and bathrooms were suitable for what market in area expects. This is more than needed by my wife and I, but makes the house marketable when we no longer want to be here and reduces the likelihood that it will be torn down or significantly renovated for decades to come.

- Ensure guest bedroom is as far away from master bedroom as possible. This also holds true for the ‘TV’ room.

- Ensure sufficient closet space in all rooms (including bathrooms).

- Minimize extent of hall (another area grossly out of proportion in many 'modern' dwellings).

- Make bathrooms big enough without wasting space.

- Meet personal desire for more luxurious master bedroom located at the SW corner of the floor. Placing master bedroom in this location will allow that room to most benefit from solar gain in the shoulder months.

- Ensure walls are available for required seismic bands to line up with bands below.

- Meet my wife’s one and only requirement of a walk in closet in the master bedroom (yes I have it easy).

|

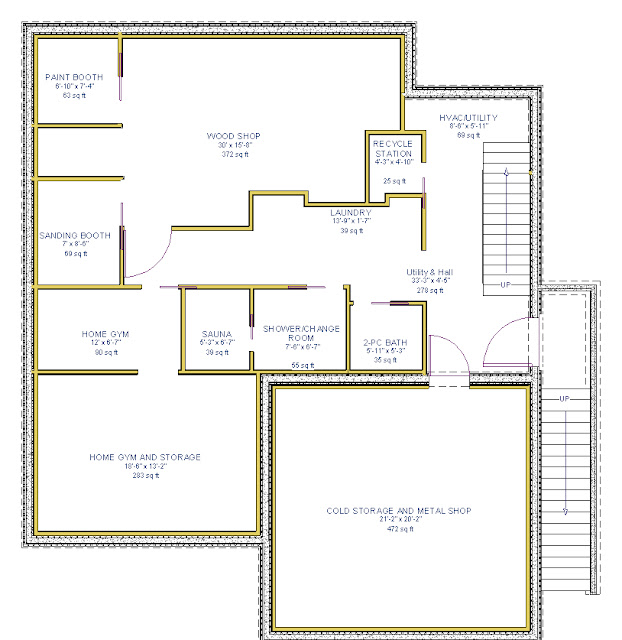

| Fig 8 - Basement |

Design Considerations:

- Contain all HVAC equipment.

- Provide Laundry facility where noise will not be disturbance to occupants. Also reduces flood hazard by not having it on upper floors (Holmes would be proud!).

- Provide space for home gym (first hurtle, actually using it is the hardest).

- Fulfill life long dream of a full wood shop.

- Provide Waste Vegetable Oil fuel processing station (upcoming blog entry).

- Provide for computer LAN vault.

- Provide for ample storage.

- Accommodate a Sauna.

Wednesday, 28 November 2012

The problem with architecture is architects!

Some of you who know me, know my general bias against the architectural profession. I have built up this bias over many years for many reasons, but primarily due to the lack of respect many of their designs show to good building science.

Well today was grounds to again support this bias and I just can't keep my thoughts contained. Against my better judgment, I attended the Sustainabuild conference in Vancouver which is geared towards the architectural community. My draw was one of the speakers - Murray Frank - who I highly respect and was one of the only real rays of sunshine in an otherwise cloudy and stormy day. Fortunately he provided a presentation on good science or my head would have exploded with all of the assaults to good building science presented throughout most of the day's balance.

Let me give you some examples. I just about bit through my tongue when one of the early presenters discussed Chicago's Aqua tower shown in the photos below and advised "we can design buildings that are able to capture solar energy".. "and get rid of excess heat within the building".

Are you kidding me?

The Aqua tower is an abomination to all good building science practices and pretty much eliminates the ability to separate the exterior from the interior environment due to its extreme solar bridging and moisture transport by means of the extended floor slabs. I can advise that in the heart of the summer, you still need to have the heat turned on during cloudy days (I have the unfortunate distinction of having stayed at the hotel during a recent vacation - my wife booked the place before I realized where it was).

But the tower won some awards and was designed by a women and is pursuing the LEED certification, so it must be a good thing - right?

Wiki states "Sustainability was an important factor in Aqua's design. Gang and her team refined the terrace extensions to maximize solar shading, and other sustainable features will include rainwater collection systems and energy-efficient lighting. The green roof on top of the tower base will be the largest in Chicago."

Why not try and make the building enclosure bullet proof before worrying about small energy contributors like lights and rainwater collection.

Green roofs have been proven many times to not be green (they often do not reduce storm runoff, make for poor performing insulation, often need to be watered to stay alive, are often poorly installed leading to leaks, and the list goes on). The only reason for them is a visual pleasantry and no one is going to see this one being on the top of one of the tallest buildings in the area.

The same presenter then tried to advise the room, towers are less green than low rises because they use more energy per cubic meter due to the need to "pump all that water up all those floors". A figure of 1100 units (believe it was kWh/m2/annun) was identified for the towers and a much lower figure was used in their example for low and mid rise units. This person was advocating that we take up more land for buildings, make the buildings shorter, and that the result would be that we needed less 'green' space and parks because there would be less shading from neighbouring buildings and I guess indicates people would be more comfortable staying in their little cubby holes.

Fortunately there was a presenter later in the day who represented the Marine Gateway project at Marine Drive and Cambie in Vancouver. He had actual numbers from the modelling of the development which were down around 100 units which represent a very attractive target and a well run efficient building. But what if he was not in the room. The first presenter's assertion that towers equated to energy inefficiency would have prevailed and could have started a whole new push by the architectural community based on poor concepts using inaccurate data.

Besides Murray's presentation, the only other ray of hope in the room for me, was the fellow who presented on the Cambie Corridor densification project and specifically the Marine Gateway project. This project appears to be a great step towards sustainable multi-family living. There is only 50% glazing in the residential and 51% in the commercial spaces (compared to 75%-90%+ for many downtown buildings). The presenter went on to say that the areas that are not glazed are heavily insulated. Finally a team with their priorities straight. Get the building envelope right and you will have a low energy and 'green' building.

An example was made early in the day that showed the lotus car and had the presenter discussing how beautiful the cars exterior was and the true marvel was how the engineers were able to fit everything that was NEEDED into that 'beautiful' shape to make that shape FUNCTIONAL.

I see this process as being the biggest fundamental flaw with the architectural community.

We need to abolish this process and instead first decide on our performance goals, define our building enclosure to meet those goals using good building science, and only then allow the architects into the fray to design the perceived 'beauty' into the buildings. But only up to the point that the client can afford, after committing to the performance objectives first, and only to the point that the architects design does not impend the designed enclosure that is needed to meet the performance objectives.

Only then will our building start to become legacies instead of liabilities and truly be 'green'!

Well today was grounds to again support this bias and I just can't keep my thoughts contained. Against my better judgment, I attended the Sustainabuild conference in Vancouver which is geared towards the architectural community. My draw was one of the speakers - Murray Frank - who I highly respect and was one of the only real rays of sunshine in an otherwise cloudy and stormy day. Fortunately he provided a presentation on good science or my head would have exploded with all of the assaults to good building science presented throughout most of the day's balance.

Let me give you some examples. I just about bit through my tongue when one of the early presenters discussed Chicago's Aqua tower shown in the photos below and advised "we can design buildings that are able to capture solar energy".. "and get rid of excess heat within the building".

Are you kidding me?

The Aqua tower is an abomination to all good building science practices and pretty much eliminates the ability to separate the exterior from the interior environment due to its extreme solar bridging and moisture transport by means of the extended floor slabs. I can advise that in the heart of the summer, you still need to have the heat turned on during cloudy days (I have the unfortunate distinction of having stayed at the hotel during a recent vacation - my wife booked the place before I realized where it was).

|

| The Aqua Tower in Chicago - Photo by your author Summer 2012 |

| |||||||

| Thermograph image showing the extreme heat bridging present in this building (Notice the 20º Celsius spread in temperatures) - Photo http://www.healthyheating.com |

Wiki states "Sustainability was an important factor in Aqua's design. Gang and her team refined the terrace extensions to maximize solar shading, and other sustainable features will include rainwater collection systems and energy-efficient lighting. The green roof on top of the tower base will be the largest in Chicago."

Why not try and make the building enclosure bullet proof before worrying about small energy contributors like lights and rainwater collection.

Green roofs have been proven many times to not be green (they often do not reduce storm runoff, make for poor performing insulation, often need to be watered to stay alive, are often poorly installed leading to leaks, and the list goes on). The only reason for them is a visual pleasantry and no one is going to see this one being on the top of one of the tallest buildings in the area.

The same presenter then tried to advise the room, towers are less green than low rises because they use more energy per cubic meter due to the need to "pump all that water up all those floors". A figure of 1100 units (believe it was kWh/m2/annun) was identified for the towers and a much lower figure was used in their example for low and mid rise units. This person was advocating that we take up more land for buildings, make the buildings shorter, and that the result would be that we needed less 'green' space and parks because there would be less shading from neighbouring buildings and I guess indicates people would be more comfortable staying in their little cubby holes.

Fortunately there was a presenter later in the day who represented the Marine Gateway project at Marine Drive and Cambie in Vancouver. He had actual numbers from the modelling of the development which were down around 100 units which represent a very attractive target and a well run efficient building. But what if he was not in the room. The first presenter's assertion that towers equated to energy inefficiency would have prevailed and could have started a whole new push by the architectural community based on poor concepts using inaccurate data.

Besides Murray's presentation, the only other ray of hope in the room for me, was the fellow who presented on the Cambie Corridor densification project and specifically the Marine Gateway project. This project appears to be a great step towards sustainable multi-family living. There is only 50% glazing in the residential and 51% in the commercial spaces (compared to 75%-90%+ for many downtown buildings). The presenter went on to say that the areas that are not glazed are heavily insulated. Finally a team with their priorities straight. Get the building envelope right and you will have a low energy and 'green' building.

An example was made early in the day that showed the lotus car and had the presenter discussing how beautiful the cars exterior was and the true marvel was how the engineers were able to fit everything that was NEEDED into that 'beautiful' shape to make that shape FUNCTIONAL.

I see this process as being the biggest fundamental flaw with the architectural community.

We need to abolish this process and instead first decide on our performance goals, define our building enclosure to meet those goals using good building science, and only then allow the architects into the fray to design the perceived 'beauty' into the buildings. But only up to the point that the client can afford, after committing to the performance objectives first, and only to the point that the architects design does not impend the designed enclosure that is needed to meet the performance objectives.

Only then will our building start to become legacies instead of liabilities and truly be 'green'!

Labels:

Aqua tower,

Energy Efficient Building,

Green Architecture,

LEED,

Passive House,

PassivHaus,

Sustainability,

Sustainabuild

Location: North Vancouver

1705 Marine Dr, North Vancouver, BC V7P 1V3, Canada

Sunday, 11 November 2012

Fall 2012 Energy Efficiency Public Review

BC has been pursuing energy conservation and greenhouse gas

reduction goals in buildings for more than five years. In September

2008, the Province adopted new energy and water efficiency objectives

and requirements for all buildings in the British Columbia Building

Code. Since that time, staff have been working on the next steps to

improve energy efficiency in buildings consistent with the goals in the

Clean Energy Act (2010).

We invite your feedback on a set of proposals to adopt updated energy efficiency requirements in the British Columbia Building Code, including:

Large Residential, Industrial, Commercial and Institutional (Part 3) Buildings: A proposal to reference both the 2011 National Energy Code for Buildings (NECB) and ASHRAE 90.1 – 2010 as two possible compliance options in the BC Building Code.

Housing and Small Buildings (Part 9): A proposal to adopt the package of new revisions to the National Building Code relating to energy efficiency for housing and small buildings.

Ventilation (Part 9): A proposal to adopt new ventilation requirements for Part 9 housing to maintain occupant health and safety.

The proposed changes would have an impact on Part 10 in the BC Building Code. If these proposals are adopted, Part 10 would look like this.

We invite your feedback on a set of proposals to adopt updated energy efficiency requirements in the British Columbia Building Code, including:

Large Residential, Industrial, Commercial and Institutional (Part 3) Buildings: A proposal to reference both the 2011 National Energy Code for Buildings (NECB) and ASHRAE 90.1 – 2010 as two possible compliance options in the BC Building Code.

Housing and Small Buildings (Part 9): A proposal to adopt the package of new revisions to the National Building Code relating to energy efficiency for housing and small buildings.

Ventilation (Part 9): A proposal to adopt new ventilation requirements for Part 9 housing to maintain occupant health and safety.

The proposed changes would have an impact on Part 10 in the BC Building Code. If these proposals are adopted, Part 10 would look like this.

Labels:

Energy Efficient Building,

Energy Efficient Home,

Insulation Values,

PassivHaus,

Sustainability

Location: North Vancouver

EB Marine Dr FS Tatlow Av, North Vancouver, BC V7P, Canada

Thursday, 13 September 2012

Alfie the Excavator joins the SENWI Team!

When I was younger, I always wanted a fancy tractor to play in the sand box. Well 40 years later I got one.

We would like to welcome Alfie the Mini-Excavator to the SENWI team. Alfie spent most of his life up in the Whistler, BC area where he worked on the rock gang and was often left out in winter's cold cold harsh weather. We at SENWI wanted to rescue Alfie and let him live out his senior years in the relative comfort of the lower mainland.

Alfie has an impressive 10ft digging depth and due to his rigorous exercise schedule is able to fit through a 5'3" opening. So he is great for those small back yard projects you have been putting off. He loves to dig and is quite skilled at digging a small trench for a perimeter drainage system. For fun he likes to knock out stumps, small trees, and brush and has even been know to transplant the odd bush or two. His thumb makes it child's play for him to move around rocks or slabs in the various landscaping projects he will be helping us with.

We decided to ask Alfie to join our team, as I anticipated having a large volume of landscaping to be done on our build. Having a help like Alfie on site during the build itself will also be invaluable. He has already provide some ideas on how to create a small deck on his boom to help me lift materials up to the second floor and claims he is up to the task of removing our structure and concrete slab when we tear down our existing dwelling. He also can't wait to show his brawn and lift in all the heavy beams I will have on the first floor ceiling.

A friend of Alfie costs $3200 a month to rent. If we only rented when we really needed a helper like this, then we would not have one around for all the small jobs that Alfie will be great at. At a minimum, we would need one of Alfie's friends for a period of 6 months at a minimum cost of $19,200 + Tax. At a purchase price that was less than this, Alfie just makes financial sense.

His arrival has also sparked up interest in the neighbourhood and he has already been asked to play at two yards nearby which of course helps reduce his purchase costs. For longer trips, he has made friends with Butch the tow truck during his trip down from Whistler, so that he can get out and play in other yards on occasion.

We would like to welcome Alfie the Mini-Excavator to the SENWI team. Alfie spent most of his life up in the Whistler, BC area where he worked on the rock gang and was often left out in winter's cold cold harsh weather. We at SENWI wanted to rescue Alfie and let him live out his senior years in the relative comfort of the lower mainland.

Alfie has an impressive 10ft digging depth and due to his rigorous exercise schedule is able to fit through a 5'3" opening. So he is great for those small back yard projects you have been putting off. He loves to dig and is quite skilled at digging a small trench for a perimeter drainage system. For fun he likes to knock out stumps, small trees, and brush and has even been know to transplant the odd bush or two. His thumb makes it child's play for him to move around rocks or slabs in the various landscaping projects he will be helping us with.

We decided to ask Alfie to join our team, as I anticipated having a large volume of landscaping to be done on our build. Having a help like Alfie on site during the build itself will also be invaluable. He has already provide some ideas on how to create a small deck on his boom to help me lift materials up to the second floor and claims he is up to the task of removing our structure and concrete slab when we tear down our existing dwelling. He also can't wait to show his brawn and lift in all the heavy beams I will have on the first floor ceiling.