While this is a lofty ideal and worth pursuing, a reality check often shows that while a material is technically recyclable, there often (usually) not programs in place to actually process the used material. During the deconstruction of my house, I ran into two good examples.

My kitchen floor was pure linoleum tiles (essentially linseed oil). This is a product that can be composted or used as fuel for large scale heating boilers. But in my region, there was no program set up to process the product and I ended up taking it to the landfill (I did not have the facilities to grind up and compost myself).

The second product I failed to recycle was all of the plastic pipe I salvaged from below grade. This included PVC drainage pipe, PVC irrigation pipe, and ABS sewer pipe. For this commodity, there was a program in place to recycle the material, but only if it was VERY clean (think like new). The process available could not handle pipe with any dirt or other sediment on it. SO in the end, it too had to go to the landfill.

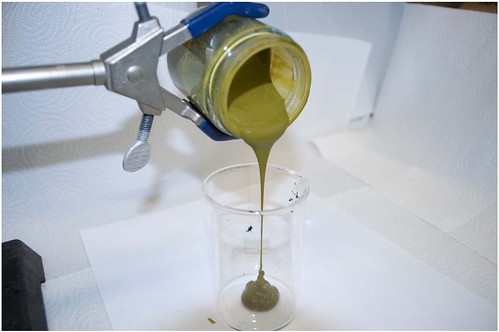

| |||

| Misc Pipe and Plastic that was not accepted at recycling facility. |

I see too many 'green' building designs that choose a 'green' product due to a promised carbon footprint as the primary focus, without ensuring the product will be durable long term in service. This often will result in the need to replace the product after a very short life cycles. Even if the product can be returned back to the raw material supply chain, this still represents an increased burden on the planet compared to a competitive product that while being less 'green', is more durable in service. And if the 'green' product cannot be returned to the supply chain, you are just that much further behind.

Instead, my focus is to start at the most durable end of the spectrum and then try to pick products with lower embodied energy characteristics from the high performance candidates, AND install the products per best practices to ensure they are as useful and durable as possible.

My long term hope is that the cost of new materials becomes so high that even the main stream players in the market see recycling as a no-brainer. This would address the fact that right now, recycling often does not make sense from strictly a financial platform. However part of the problem is also the technical challenges in recycling a product.

Fortunately, there is some visionaries that have been working for many years to solve some of these hurdles. Mike Biddle has been working on a system that can separate bulk shredded plastics into the different colours and materials solving one of the biggest stumbling blocks to mass recycling of plastics (read PopSci article for full storey). The beauty of his system is that this is all done in N.A., saving the need to ship offshore, via an automated process (no high labour costs). By keeping the product on our shores, we reduce the pollution our society is creating within poorer countries.

Lets hope others are working on the myriad of other materials we as a society currently just discard.